Climbing crane LCC140

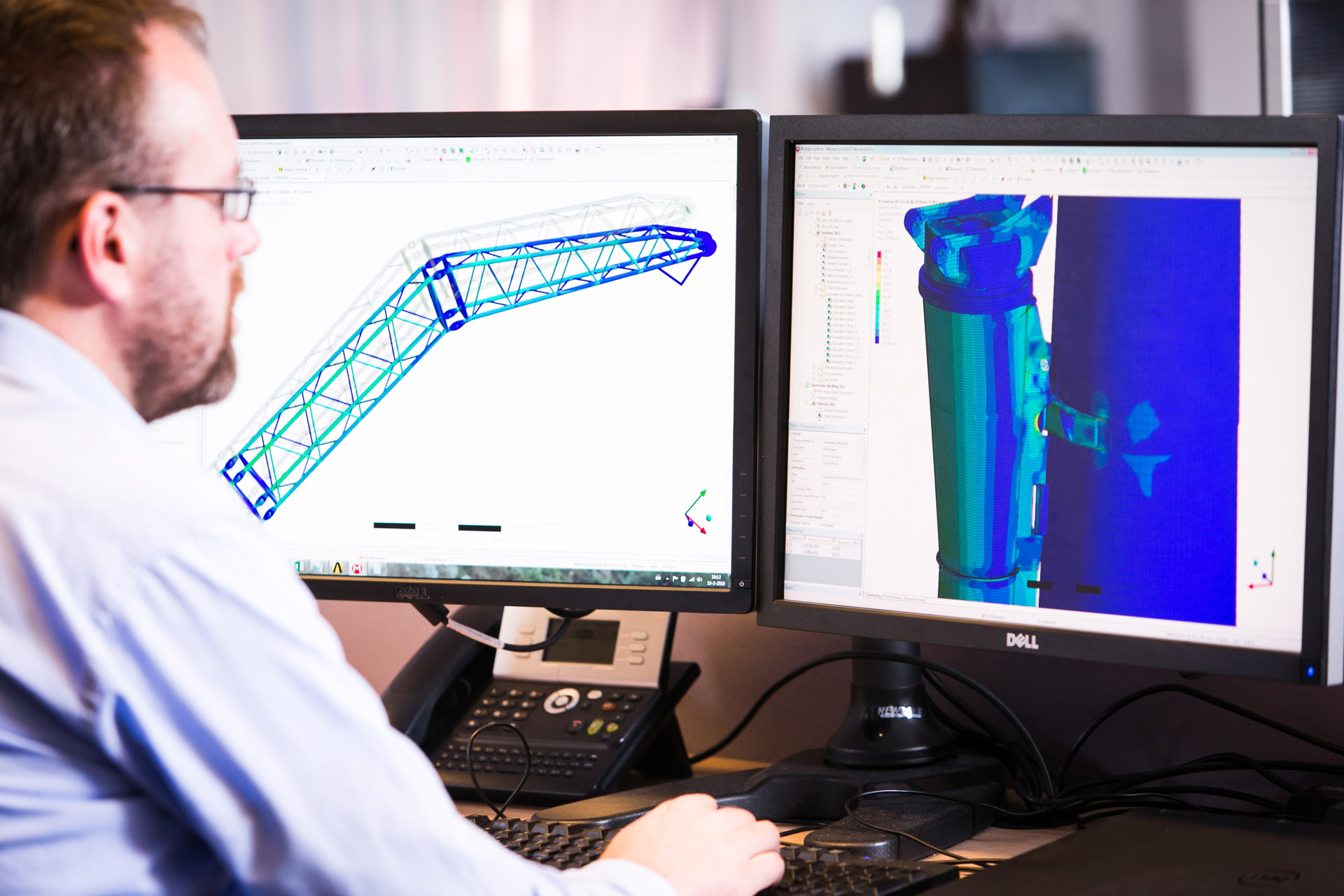

In 2017 the first design, the LCC60, was ready: a crane with one winch that can lift 60 tons. With six hydraulically extendable arms between the crane and the mast of the turbine, the crane could pull itself up. After the LCC60, Lagerwey, part of turbine builder Enercon GmbH, was looking for a second climbing crane that can lift up to 140 tons to build larger wind turbines. Just like with the first climbing crane, the wind turbine builder went to engineering firm MechDes Engineering, which took care of the concept, basic and detailed engineering of the LCC140.

The LCC140 builds up the wind turbine tower and then uses it to climb further up. At the very top, the crane places the nacelle, generator, hub and blades.

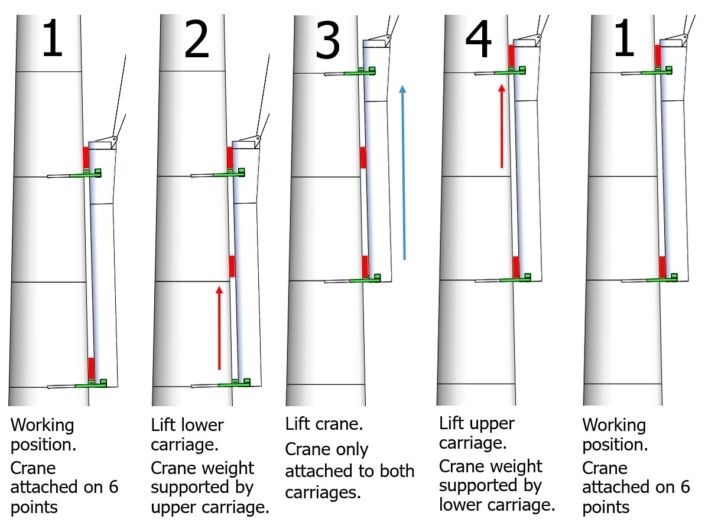

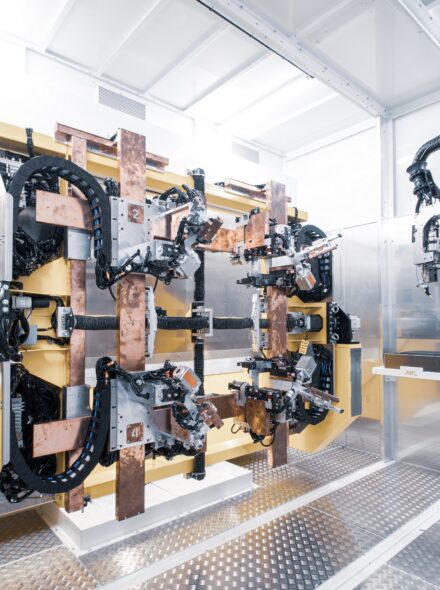

Simply making everything bigger than with the LCC60 would not work, because the load on the wind turbine tower would be too great. The solution for this is two stabilizing arms that clamp themselves half around the mast like a child with its mother, thereby distributing the load on the tower. Furthermore, the LCC140 attaches itself to the crane points made in the mast with two so-called carriages. When climbing, the lower carriage slides to a higher crane point. The upper carriage releases the mast, after which the crane pushes itself upwards. The top carriage also anchors itself again to a crane point. The tap is now ready for use again.

The LCC140 also has a so-called blade beam, with which the crane lifts a turbine blade on two cables, so that it can also mount blades at wind force 6, without having to use steering lines. The LCC140 shortens the total construction time of a wind turbine considerably compared to a conventional crane and you are less dependent on wind-poor days. Other advantages of the LCC140 are the limited use of trucks for transporting the crane (>100 versus now 11 trucks) and the construction on site requires a much smaller piece of land than with a conventional crane, which you assemble horizontally. With the LCC140 you can place wind turbines in locations where this was not possible before. Two of these cranes have already been built and are fully operational.