Skiddingsysteem

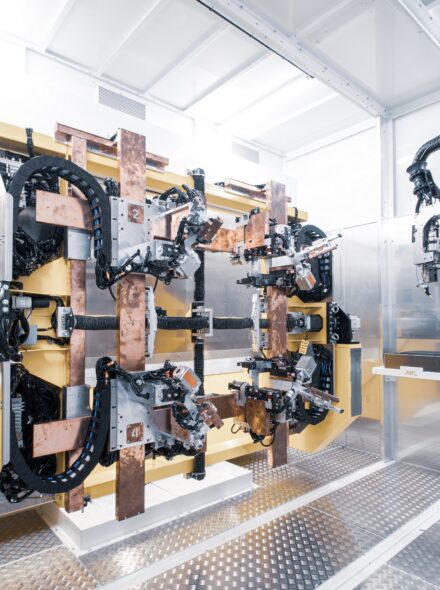

EQUIPMENT DAT ONDER DE ZWAARSTE OMSTANDIGHEDEN MOET FUNCTIONEREN

Voor haar opdrachtgever IHC Offshore Systems, een bedrijf voor o.a. uitrusting en schepen voor de offshore- en baggermarkten, ontwierp MechDes een skiddingsysteem. Dit systeem wordt gebruikt bij werkzaamheden aan oliebronnen vanaf het schip de Helix Seawell. Alle equipment op de Helix Seawell is compleet vervangen door het nieuwe skiddingsysteem. Voor deze opdracht deden we zowel het basis- als het detailontwerp, inclusief sterkte- en vermoeiingsberekeningen.

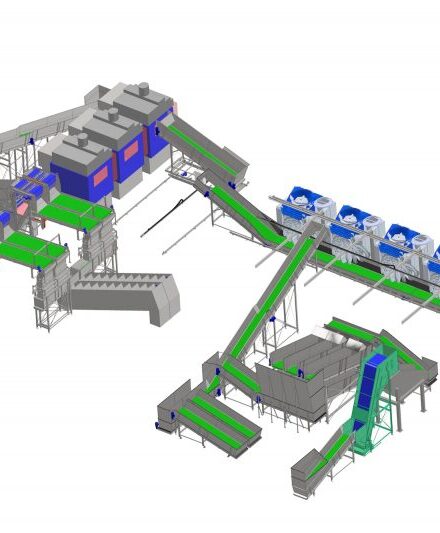

Het skiddingsysteem staat op een pallet, vanuit de toren kan dit bediend en onderhouden worden. Het gehele systeem kan tussen de parkeer- en moonpoolpositie van het schip heen en weer skidden.

Het skiddingsysteem bestaat uit een pallet van 5 x 4 meter waaraan twee push-pullsystemen gekoppeld zitten. Deze systemen kunnen het geheel van de parkeerpositie tot boven de moonpool skidden. Dit betreft een afstand van ca. 5,5 meter. Op de pallet staat een toren van ca. 27 meter hoog, waaraan de equipment vastgemaakt kan worden. Om de 3 meter zit een platform voor onderhoud. De equipment op het skiddingsysteem heeft een gewicht van 120 ton en is ca. 4 x 4 x 23 meter (lxbxh).