Klimmende kraan (Climbing crane) LCC60

DE WERELD VAN WINDTURBINES GAAT VERANDEREN

Lagerwey uit Barneveld produceert sinds 1979 innovatieve windturbines. Zij wilden turbines met een op afstand bestuurbare kraan kunnen bouwen. Deze kraan moest tijdens de constructie langs de mast van de windturbine omhoog kunnen klimmen. Met dit idee en een tekening kwamen ze bij MechDes.

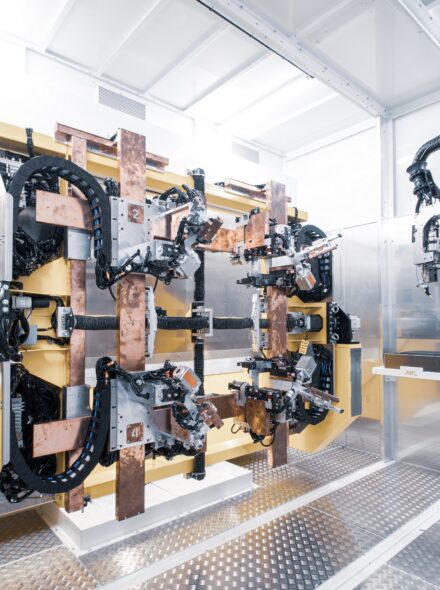

Wij hebben het idee vervolgens uitgewerkt naar een ontwerp, een hijskraan voor het bouwen van de turbines. Deze kraan klimt omhoog langs de mast van de windturbine. De kraan kan 60 ton op een afstand van 6 meter tillen.

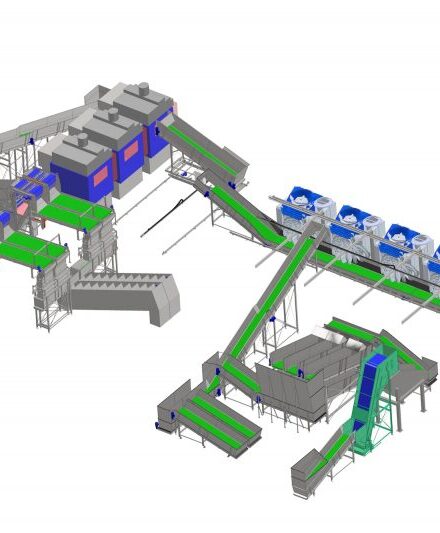

Binnen de sector ‘windenergie’ zijn grote windturbines de trend. Echter, de installatie van deze reuzen wordt steeds complexer. Zo is voor de installatie van een multi-megawatt windturbine met een hub-hoogte van meer dan 150 meter, een grote en dure kraan nodig. Het vervoer van een dergelijke kraan kan alleen in onderdelen en dat vraagt om de inzet van veel vrachtwagens. Het assembleren en disassembleren van een kraan duurt meerdere dagen. Omdat assemblage horizontaal plaatsvindt, is de beschikbaarheid van een groot en vlak terrein nodig, evenals een degelijke ondergrond.

Calculaties

In een project als dit bestaat de helft van de engineering uit het maken van calculaties. Allereerst moest de belastbaarheid van de kraan worden geïdentificeerd. Naast de normale belasting, zoals tillen en klimmen, moest de kraan ook bestand zijn tegen een zware storm van meer dan 12 Beaufort. Het ontwerp, inclusief calculaties moest worden goedgekeurd door een officiële instantie, die tevens controleerde of de kraan zou worden gebouwd volgens de juiste specificaties. In de meeste gevallen maakten we hierbij gebruik van FEA (Finite Element Analysis) met Ansys, om de stress en stabiliteit te controleren. Ook de sterkte van de boutverbindingen, staalkabel en lagers werd gecalculeerd. Daarnaast werd het dynamische gedrag tijdens hijsen en zwenken van de lading aan de staalkabel geanalyseerd. Om het gewicht van de kraan te minimaliseren ten behoeve van transport en het verminderen van de kracht die wordt uitgeoefend op de windturbine, pasten we voornamelijk hoogwaardig staal toe. Het staal had een treksterkte van 690MPa of zelfs 770MPa. Dat is twee tot drie keer hoger dan normaal staal!

We ontwierpen tevens de lier. Deze bevat 1600 meter van Ø19 milimeter staalkabel in 7 lagen. Voor een goede opwikkeling werd de lierdrum uitgerust met Lebusgroeven. De kraan kan worden getransporteerd door slechts drie trucks en binnen één dag worden gemonteerd. Het is ’s werelds eerst klimkraan voor windturbines en deze zal de wijze waarop turbines gebouwd worden gaan veranderen!

Facts & Figures

- Veilige werklast 60 tons

- Hijshoogte 180 m

- Draagwijdte 0,65-28,25 m

- Draaihoek angle 2×210°

- Hijssnelheid 20 m/min

De gepatenteerde kraan wordt momenteel gebouwd en zal begin 2018 worden getest.