Bladhefgereedschap en roterend naafgereedschap voor windturbines

WERKEN OP GROTE HOOGTE

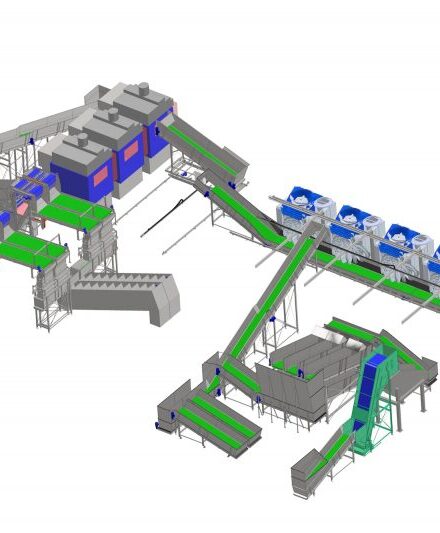

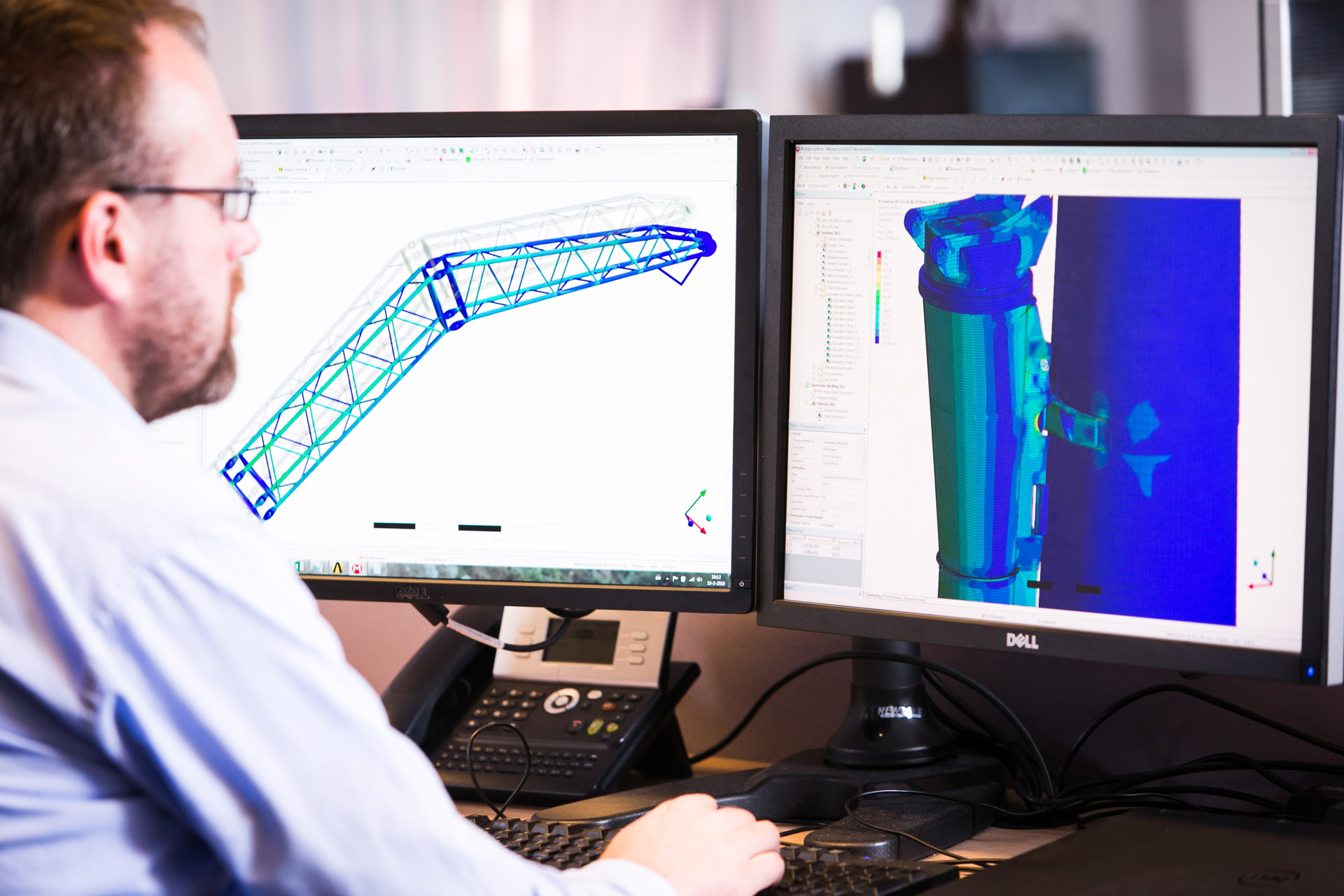

Voor haar opdrachtgever Lagerwey, een Nederlandse fabrikant van windturbines, ontwierp MechDes een gereedschap voor het hijsen van de generator en het roteren van de hub naar de juiste positie. Daarnaast ontwierpen we een hijsgereedschap voor het plaatsen van de 66,5 meter lange bladen.

Voor het eerste gereedschap ontwierpen we een tweetal pinion-drives als aandrijving, voor het richten van de windturbine in de juiste windrichting. Het tandwiel is opgebouwd uit meerdere dunne platen van hogesterktestaal, die op elkaar zijn geklemd. De vorm van deze platen wijkt onderling licht af, zodat de kracht goed wordt verdeeld.

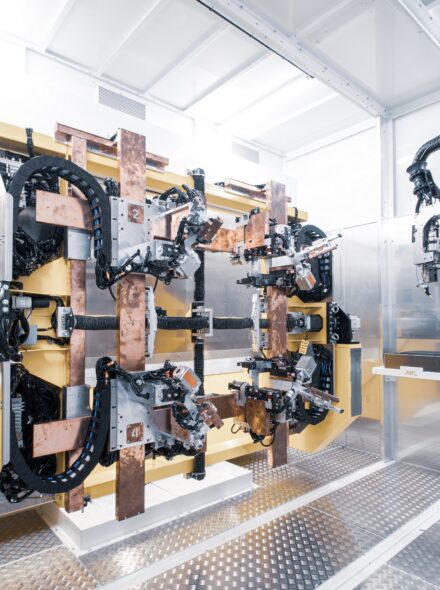

Voor het andere gereedschap ontwierpen we twee hijsinstrumenten voor het monteren en demonteren van de 66,5 meter lange bladen. Deze gereedschappen worden om de wiek geklemd voor voldoende grip. Het is belangrijk om de druk op de wiek te beperken, zodat deze niet beschadigd raakt.

Beide gereedschappen zijn inmiddels naar volle tevredenheid ingezet in het veld.